In the following we are giving a brief outline, which we try to make suitable also for the non-expert reader, about the technology and physical principles underlying the PULSe project sensor system, which is based on stimulated Brillouin scattering effect along single-mode optical fibers, and exploits a technique called Brillouin optical time-domain analyisis (BOTDA) for the interrogator equipment.

Introduction

A Brillouin sensing solution comprises a sensing fibre cable, that has to be installed or displaced along the asset to be monitored, and a sensor interrogator equipment that creates the “virtual sensor” that is swept along the cable length to measure the distribution of deformation, temperature or pressure along its whole length.

The technology is based on the Brillouin effect, an interaction between lightwaves and mechanical vibrations in which the striction induced by the electrical field of the lightwave excites mechanical waves (phonons) inside the fibre at the expense of the wavelength of the light that is interacting[1], with a linear dependence from the temperature and strain in the fibre. By analysing the wavelength of the Brillouin scattered light point-by-point along the fibre, the deformation or temperature is continuously measured just as if a “virtual” sensor would have been swept along the whole fibre length[2].

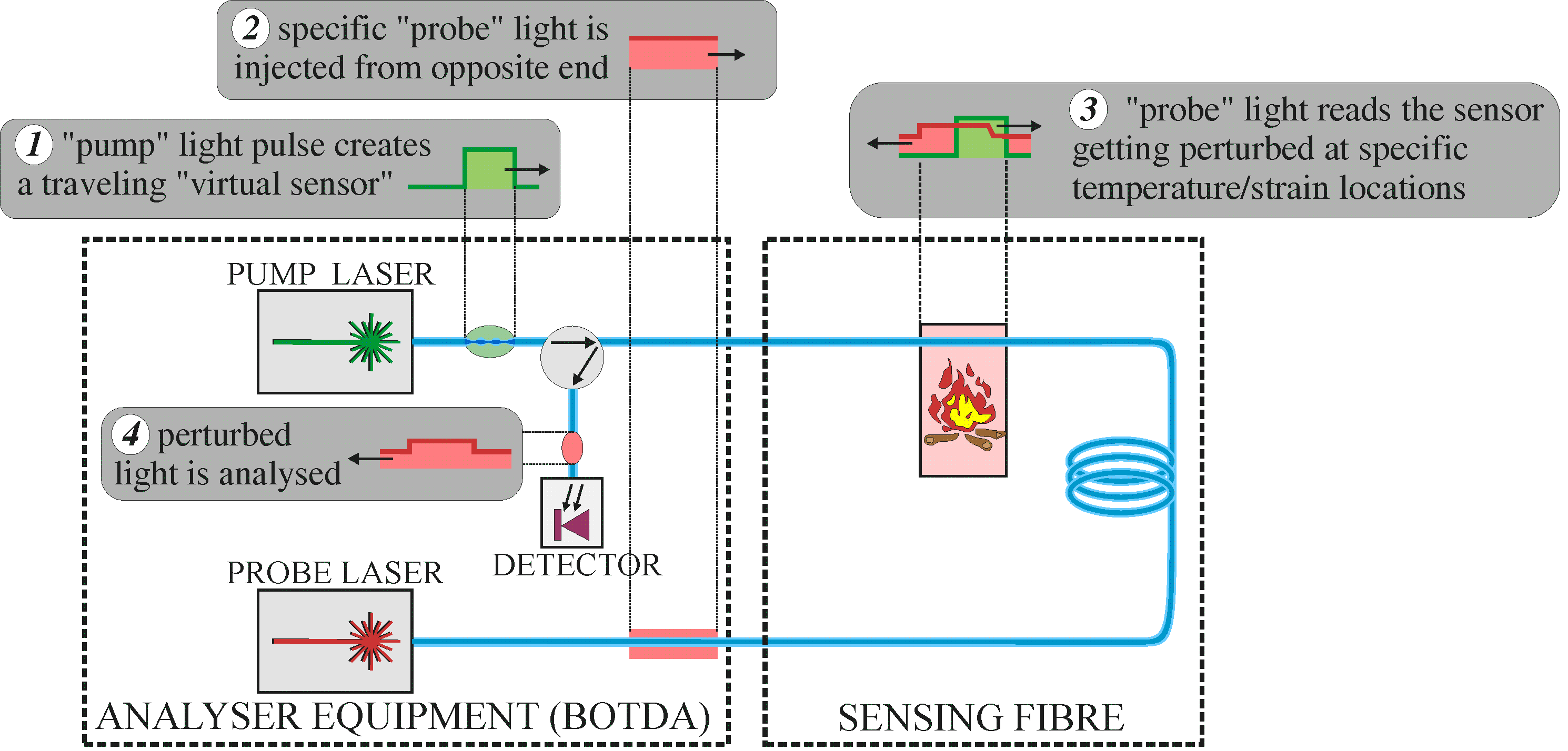

Figure 1: Basic working principle of a Brillouin Optical Time-Domain Analyser (BOTDA): the sensing point moves along the fiber in time according to the time-of-flight of the pump pulse and probe light, and the local strain/temperature measurement is done by sweeping the wavelength shift of the probe light until the maximum perturbation is detected.

State-of-the-art of this technology are Brillouin Optical Time-Domain Analyser (BOTDA) based on Stimulated Brillouin Scattering (SBS). The basic working scheme of a BOTDA is presented in Figure 1 and works as follows: (1) a pulse of “pump” light is injected at a first end of the sensing fibre and creates a travelling virtual sensor that moves along its length, while at the opposite end of the fibre (2) the “probe” light having a specific wavelength is continuously injected. When the “travelling” sensor (3) sweeps a region of the sensor that has the temperature (or strain) characteristics tested by the specific “probe” wavelength in use, the probe light results perturbed by stimulated Brillouin amplification. Perturbed light (4) is then analysed in the time-domain in order to locate the position and length of the perturbed region along the sensor.

[1] Brillouin, L., Diffusion de la Lumière et des Rayonnes X par un Corps Transparent Homogéne; Influence del’Agitation Thermique, Annales des Physique, 17, pp. 88-122 (1922).

[2] Horiguchi, T. et al., Tensile Strain Dependence of Brillouin Frequency Shift in Silica Optical Fibers, IEEE Photonics Technology Letters, 1[5], pp. 107-108, (1989).